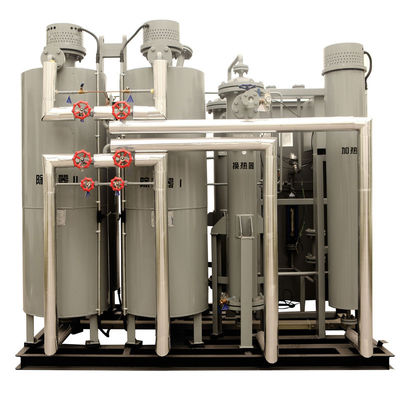

ISO 9001 Industrial oxygen manufacturing plant monoblock skid up to 5000 PSI(G) cylinders system supply

PSA Oxygen Principles

The principles of Pressure Swing Adsorption (PSA) oxygen generator are adsorption and

desorption.

Each gas has a characteristic adsorption rate that when adsorbed by Zeolite Molecular Sieve (ZMS). ZMS has large surface area containing a mass volume of micro pores and passageways. Nitrogen has a higher adsorption rate than oxygen when delivered to the ZMS bed after pressurized. When compressed air enters ZMS, oxygen molecules are able to pass through this large surface, and nitrogen molecules are adsorbed to the surface area.

Adsorption and desorption/diffusion are the general principles of the PSA system since each gas has a

characteristic adsorption rate that is a function of its ability to be adsorbed by a molecular sieve. The adsorption process can produce a range of gas with purities more than 90% oxygen.

As the ZMS is saturated with nitrogen, it should be depressurized to regenerate for next cycle. In CANGAS PSA N2/O2 generators, we use two adsorption vessels filled with ZMS to produce a continuous stream of oxygen.

During depressurization, the oxygen of lower purity than required is transferred to another vessel first, which is called pressure equalization. Pressure equalization donates to higher efficiency and less energy consumption. Then the adsorption and desorption/regeneration processes switch in the two adsorption towers.

Main features

a. All the key components adopt international celebrated branded products, such as the pneumatic and electromagnetic valves produced by GEMU and BURKET of Germany, and the PLC produced by Siemens.

b. The molecule sieve has a long service life, which effectively guarantees the oxygen purity.

c. The advanced “storm” type molecule sieve loading method provided by German Carbo Tech has greatly increased the loading density of the molecule sieve; meanwhile, the advanced combined molecule sieve pinch device may effectively prevent the pulverization of the molecule sieve caused by collision between its gaps, so the service life may be prolonged.

d. The adsorption tower adopts an advanced inner structure in design, including a lotus air flow distributor installed at the bottom of the tower, which effectively prevents the high pressure air flow crash to the molecule sieve, and also extends the service life of the molecule sieve; meanwhile, it may make the gas evenly diffuses, which greatly improves the service efficiency of the molecule sieve and reduces the energy consumption.

e. The oxygen generator adopts an optimized technological design, which makes the oxygen purity, flow rate, and pressure more stable.

f. The oxygen generator has a visual procedure display function, indicating the state of the switch valve.

| Model |

Capacity

(Nm3/hr)

|

Purity

|

Outlet pressure

(Mpa)

|

Inlet

(mm)

|

Outlet

(mm)

|

Dimensions

L*W*H (mm)

|

Weight

(KG)

|

| OSO5 |

5 |

93±3%

|

0.2-0.4 Mpa

|

DN20 |

DN10 |

1350*1200*1800 |

800 |

| OSO10 |

10 |

DN25 |

DN15 |

1800*1250*2200 |

1200 |

| OSO15 |

15 |

DN25 |

DN15 |

2100*1450*2200 |

1500 |

| OSO20 |

20 |

DN40 |

DN25 |

2300*1550*2450 |

1800 |

| OSO30 |

30 |

DN40 |

DN25 |

2450*1650*2550 |

1950 |

| OSO35 |

35 |

DN50 |

DN25 |

2650*1900*2550 |

2150 |

| OSO40 |

40 |

DN50 |

DN25 |

2800*2200*2600 |

2200 |

| OSO50 |

50 |

DN50 |

DN25 |

3100*2450*2700 |

2350 |

| OSO60 |

60 |

DN65 |

DN40 |

3300*2600*2900 |

2550 |

| OSO80 |

80 |

DN80 |

DN50 |

3500*2950*3100 |

3300 |

| OSO100 |

100 |

DN80 |

DN50 |

3850*3100*3300 |

4000 |

| OSO150 |

150 |

DN100 |

DN65 |

4100*3300*3450 |

5100 |

| OSO200 |

200 |

DN125 |

DN80 |

4600*3550*3500 |

6200 |

| OSO250 |

250 |

DN125 |

DN80 |

5500*3900*3900 |

8500 |

| OSO300 |

300 |

DN150 |

DN100 |

5800*4200*3980 |

10500 |

Design reference :

Compressed air inlet pressure 7.5 bar(g)/108 psi(g)

Air quality 1.4.1 according to ISO 8573-1:2010

Oxygen outlet pressure 2-4 bar(g)/58psi(g)

Oxygen quality 1.2.1 according to ISO 8573-1:2010.

Designed working temperature max 50 ℃

Dew point at Oxygen outlet - 50 ℃

Notes:

Following request of oxygen generator will be customized :

Oxygen outlet pressure >4 bar(g)/58 psi(g)

Filling cylinders 150 bar(g)/200 bar(g)/300 bar(g)

Dew point < - 50 ℃

Movable/containerized , plug and play

Other special requirements as per site conditions

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!